Optical Properties of Resin Lenses

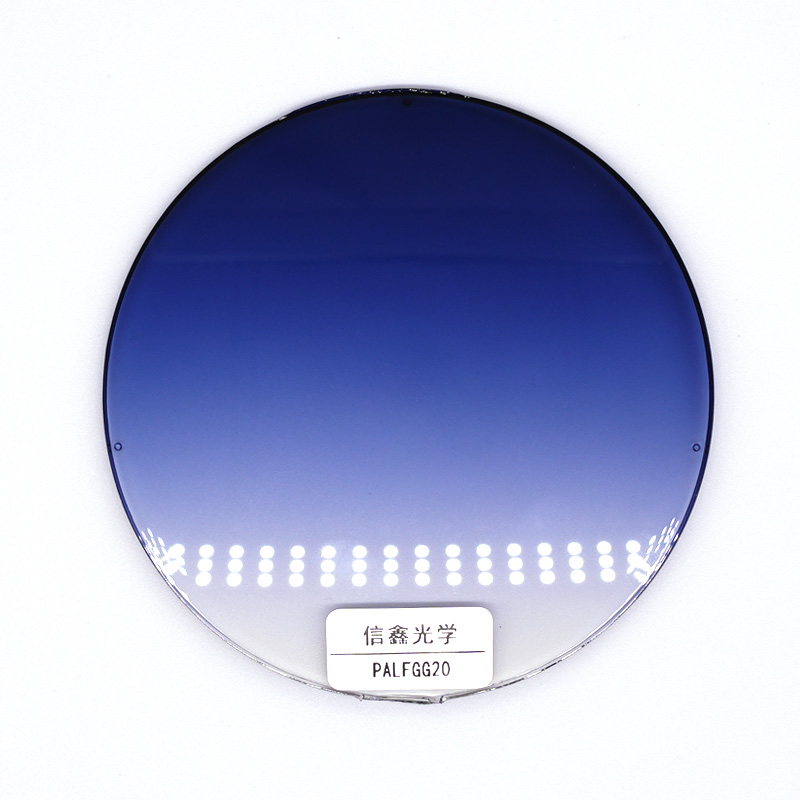

Years of development have made great progress in the surface treatment technology of resin lenses, including dyeing, impact-resistant film, anti-reflection film and top film. Especially some wearers like the lens to have a certain color for the convenience of driving, or gradually fade from the top to the bottom of the lens.

Optical Properties of Resin Lenses

The surface luster and smoothness of resin lenses are by no means inferior to ordinary glass lenses. The material density of resin lenses is lower than that of ordinary glass lenses, so resin lenses with the same power and refractive index are thicker.

The dispersion properties of resin lenses and ordinary glass lenses are very similar. The transmittance of resin lenses without cornea is poor, and the transmittance of resin lenses after coating can reach 92%, which is more than 2% higher than that of ordinary glass lenses. This kind of lens is generally used for children's mirrors with high requirements.

The surface reflection of the resin lens after coating is lower than that of ordinary glass lenses, and it is also less dazzling. This is due to its higher light transmittance and lower refractive index. The bifocal lens of the resin lens is made of a whole piece, which is not made by fusion like ordinary glass bifocal lenses. Therefore, the resin bifocal lens has no chromatic aberration.

If the lens is well cared for, it can generally be used for 2-4 years; if the care is neglected, the lens should be replaced in about 1.5 to 2 years. Wearing inappropriate lenses will cause dry and swollen eyes after prolonged use.